Steel angles are used as bracing in steel framing – Steel angles are indispensable components in steel framing, serving as the backbone of bracing systems that ensure structural stability and resistance to lateral forces. Their unique properties and versatile applications make them a cornerstone of modern construction.

Steel angles are L-shaped profiles that offer exceptional strength-to-weight ratios, making them ideal for bracing against wind, seismic, and other lateral loads. Their versatility extends to various applications, from high-rise buildings to industrial structures.

Introduction

Steel angles play a crucial role in steel framing, particularly as bracing elements. Their unique shape and properties make them ideal for providing structural stability and resistance to lateral forces. Steel angles are versatile and cost-effective, contributing to the overall integrity and safety of steel structures.

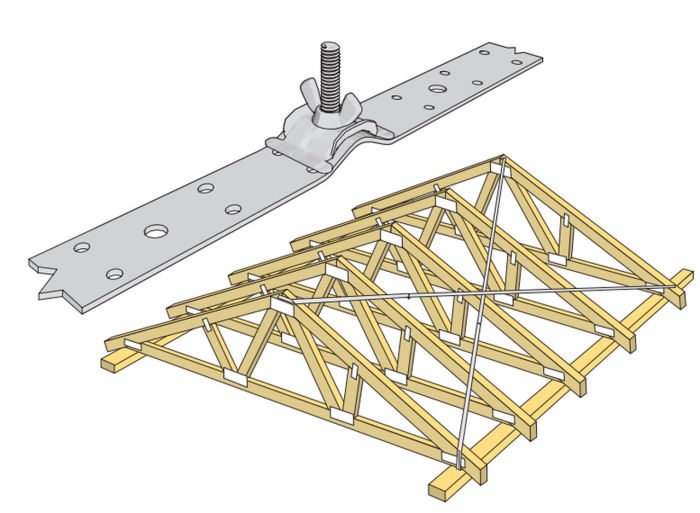

Applications of Steel Angles in Bracing

Steel angles are extensively used in various applications for bracing in steel framing. They are commonly found in:

- Building frameworks to resist wind and seismic loads

- Bridges and elevated structures for stability under traffic and environmental forces

- Industrial structures, such as warehouses and factories, to withstand heavy machinery and equipment loads

- Telecommunication towers and masts to provide support and rigidity against wind and ice loads

Design Considerations for Steel Angle Bracing, Steel angles are used as bracing in steel framing

Designing steel angle bracing systems requires careful consideration of several factors:

- Load analysis to determine the magnitude and direction of forces acting on the structure

- Material selection based on the required strength, stiffness, and corrosion resistance

- Connection details to ensure proper load transfer and prevent premature failure

- Compliance with building codes and industry standards

Installation and Fabrication Techniques

Installation and fabrication of steel angle bracing involve specialized techniques:

- Cutting the angles to the desired length and shape using saws or flame cutting

- Welding the angles together to form the bracing elements

- Assembling the bracing system and connecting it to the main structural members

- Ensuring proper alignment, fit, and weld quality

Inspection and Maintenance

Regular inspection and maintenance are crucial for the longevity and effectiveness of steel angle bracing systems:

- Visual inspections to detect any signs of damage, corrosion, or loose connections

- Non-destructive testing methods to assess the integrity of welds and structural components

- Repairs or replacements as necessary to maintain the structural integrity of the bracing system

Questions Often Asked: Steel Angles Are Used As Bracing In Steel Framing

What are the advantages of using steel angles for bracing?

Steel angles offer high strength-to-weight ratios, ease of installation, and cost-effectiveness.

How do steel angles contribute to structural stability?

Steel angles provide rigidity and resistance to lateral forces, ensuring the stability of steel framing structures.

What are some common applications of steel angles in bracing?

Steel angles are used in bracing for high-rise buildings, industrial structures, bridges, and other steel-framed constructions.